Let's

work together.

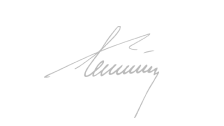

• Designed a full CAD model of a glenoid implant and performed finite-element analysis using Abaqus on CATIA-generated geometry. Implemented elastic–plastic UHMWPE material properties (E = 2100 MPa, v = 0.37) and applied 50–300 N quasi-static loading conditions to replicate physiological joint forces.

• sed additive manufacturing and ionizing-radiation to produce UHMWPE prototypes to improve wear resistance and reduce debris.

• Designed and executed a mechanical-testing protocol, instrumented the implant with strain gauges, and measured deformation using a camera-based tracking under controlled loading.

• Conducted a full literature review to map existing glenoid prosthesis designs and establish a technical state of the art.

• Designed and implemented a custom experimental protocol using electromagnetic tracking sensors (60 Hz).

• Performed 5 pointing trials on 6 subjects to quantify humerus–scapula rotational dynamics.

• Identified orientation error of 2.3°, evaluated limitations of EM tracking, proposing improvements using an optoelectronic motion-capture system.

• Managed an inventory of approximately 45 tools used in a 42 m² production line.

• Optimized storage layout based on frequency of usage and location on the production line, improving retrieval efficiency.

• Designed 3D models of each 45 tool with 3D scanners.

• Cut 9 custom foam inserts with imprints of 3D-modeled tools

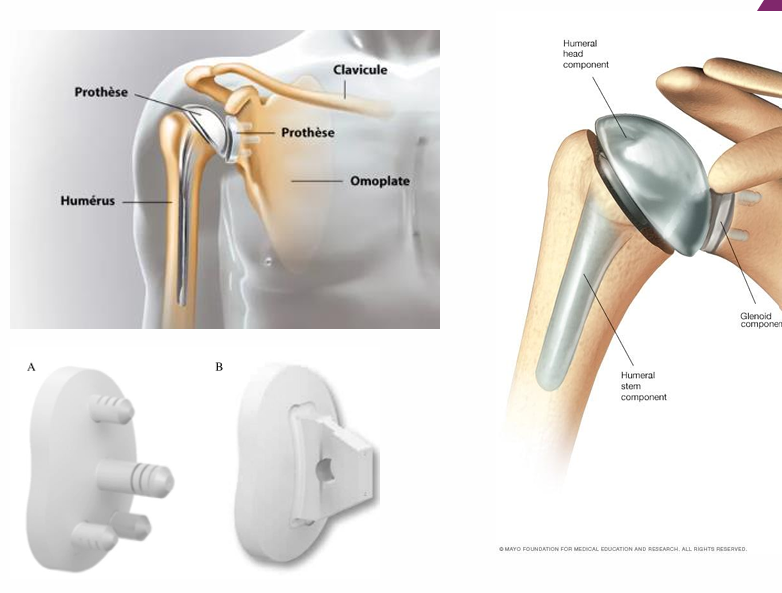

• Simulated a fully automated warehouse environment using object oriented programming including robots, conveyors and storage zones.

• Developed an adaptive A* algorithm to enable real-time pathfinding and collision avoidance in a constantly changing setting.

• Used Tkinter to create a graphical user interface for visualization and XML for data configuration and storage.

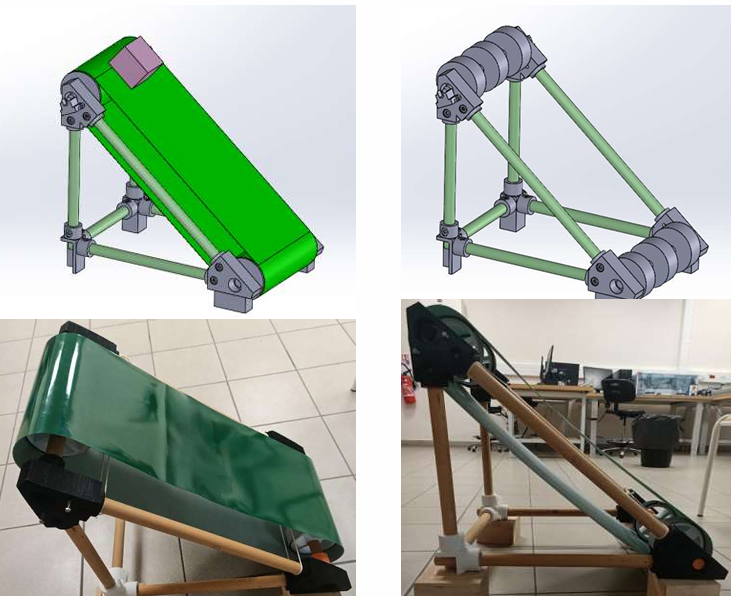

• Designed and built a life-size slide prototype to simulate electricity production.

• Used 3D modeling software to design and 3D print 12 prototype components

• Implemented a 12V-DC motor as a generator and conducted 25+ tests involving computer science, electronics, and energy science.

• Designed and analyzed automatic bar screens, including size, hydraulic and electrical parameters

• Contacted engineers at the wastewater treatment plant for technical insights.

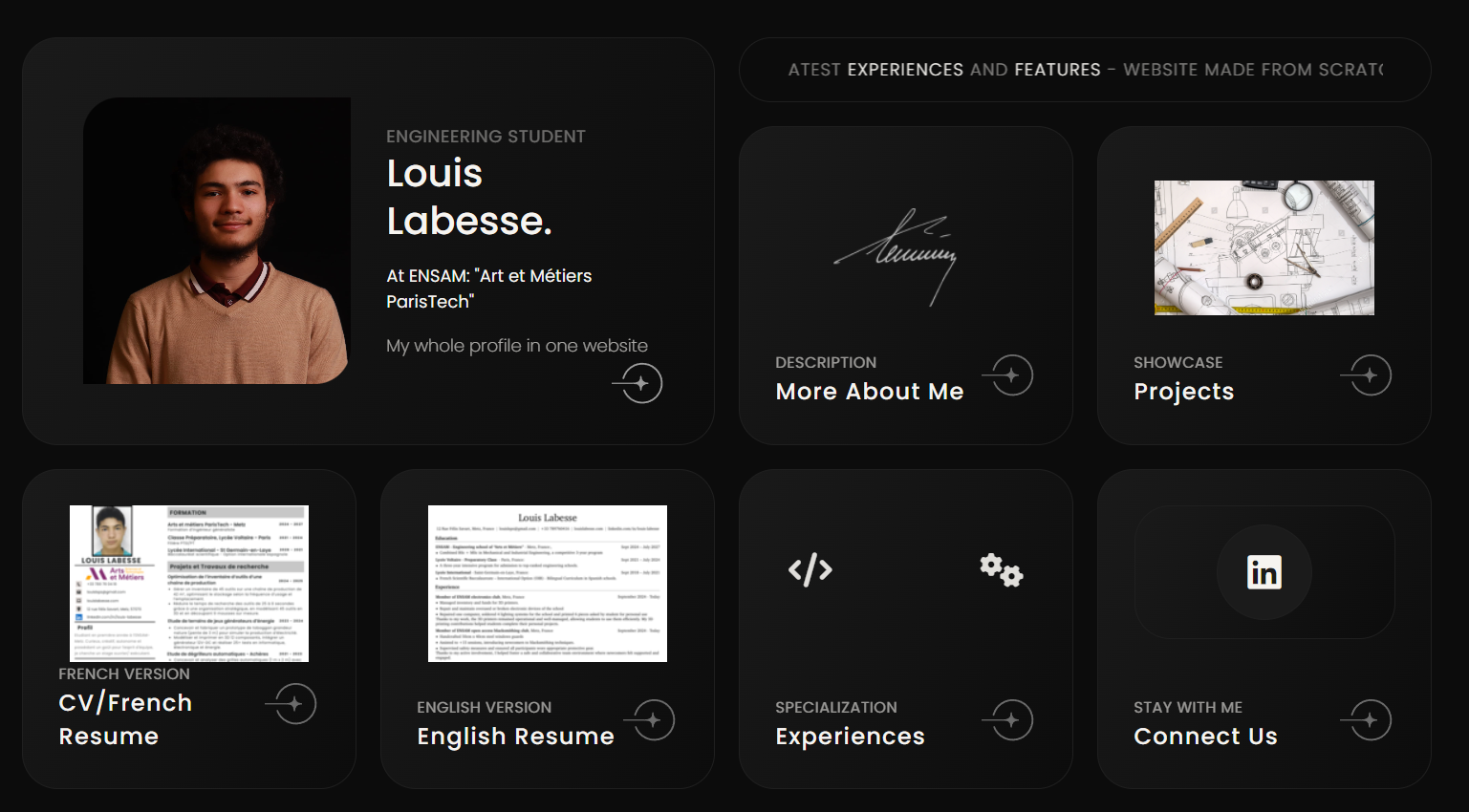

• Learned by myself CSS and HTML languages on internet while also taking courses in my engineering school

• Designed and upgraded each day my website

• Made mistakes and spent hours and days debugging to synchronize the html and css files

• Learned how do domains and https protocol work, to post my portfolio online

• Still need to adapt the format to mobile users, very difficult to do it in css